Contact us for quotation

Let's have a chat

Let's have a chat

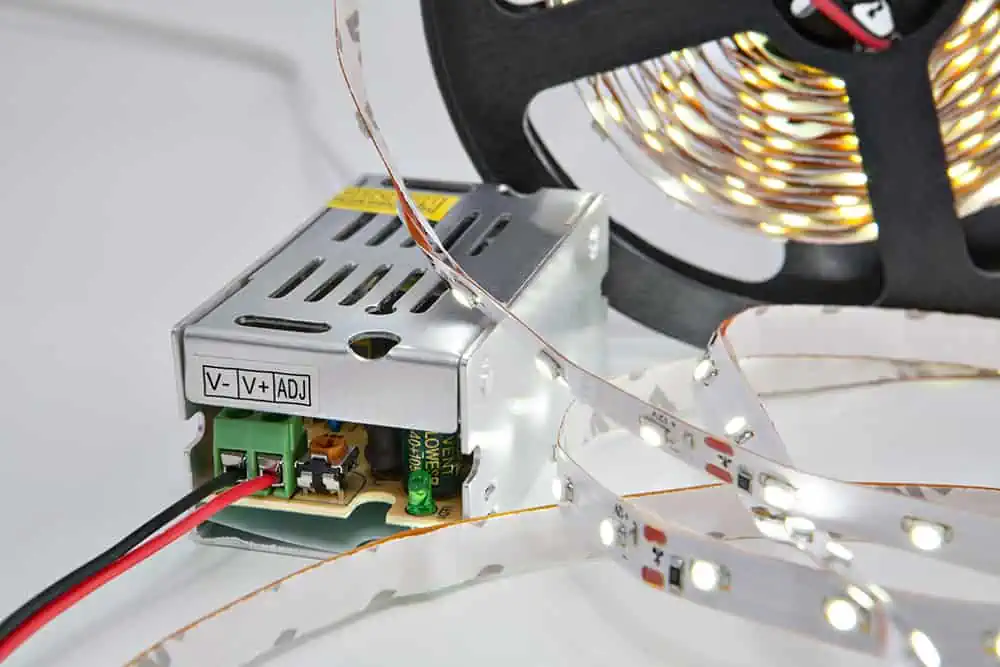

LEDs require a reliable power supply to operate. Drivers for LED lights supply this power, converting alternating current (AC) to direct current (DC). They ensure the power supply is constant and uninterrupted by compensating for changes in the temperature and electrical conductivity of the LEDs. This prevents overheating, flickering, colour changes and degraded performance.

With the tightening of energy regulations, many recognize LEDs’ long lifespan and energy efficiency (light-emitting diodes). However, it’s less known that these modern light sources need an LED driver. Think of LED drivers like the ballasts for fluorescent lights or transformers for low-voltage bulbs. They supply the necessary electricity for LEDs to operate optimally.

The role of an LED driver is to determine the power required for an individual LED or a set of them. LEDs are designed for prolonged use and minimal energy consumption, so they need specific power configurations.

LED drivers mainly serve two functions:

An individual LED typically consumes up to 30mA of current and operates between 1.5V and 3.5V. When combining several LEDs for home lighting, the combined voltage might range from 12V to 24V DC. The LED driver’s task is to convert our regular 120V-230V AC mains voltage into this required low DC voltage.

Additionally, LED drivers shield LEDs from any variations in voltage and current. They ensure LEDs consistently receive the appropriate voltage and current, thus preventing potential overloading or dimming.

Yes, all LED lights require a bulb driver to operate, but purchasing these separately is not always necessary. Some models have an integrated driver and exceptionally standard LED bulbs for domestic settings.

Lower voltage LEDs typically require a separate driver, but this has one advantage. If the Driver breaks, it can be replaced without replacing the bulb.

LEDs are sensitive to temperature changes, which can influence their voltage requirements. As the temperature rises, an LED requires less voltage to drive the current, leading it to consume more power. If left unchecked, this could cause a ‘thermal runaway,’ where escalating temperatures could destroy the LED. LED drivers are designed to manage this by adjusting to changes in the LED’s voltage needs and maintaining a stable temperature.

As transformers cater to low-voltage bulbs, LED drivers are tailored for LEDs. Standard LEDs usually operate at 4V, 12V, or 24V. They require direct current (DC) to function. However, our typical wall outlets offer a much higher voltage (ranging from 120V to 277V) and supply alternating current (AC), making them incompatible with LEDs. Since regular transformers cannot meet the specific voltage needs of LEDs, LED drivers are employed to bridge this gap, converting high-voltage AC into the necessary low-voltage DC.

Furthermore, LED drivers offer protection from power fluctuations, which can elevate temperatures and reduce light intensity. LEDs are designed to function within a specific current range.

Specific LED drivers are even sophisticated enough to adjust the brightness and sequence of colour displays in LED systems. This is achieved by precisely controlling each LED’s on/off state. For instance, producing white light might involve simultaneously illuminating multiple coloured LEDs. The desired colour or brightness can be modified by selectively deactivating some.

Internal LED drivers are typically found in bulbs and low-power indoor lights, making them more affordable and aesthetically pleasing. External LED drivers, however, are prevalent in high-power applications such as street, stadium, floodlights, and grow lights. They are placed outside due to increased heat production as power rises and are easier to replace for maintenance.

Linear LED drivers are straightforward; an LED’s constant current might require a resistor, a controlled MOSFET, or an IC. Common in AC LED, sign, and strip applications, they quickly adjust to various power supplies. However, they’re less efficient. In contrast, switching power supplies produces brighter light, lesser flicker, better power factor, and superior surge protection.

Both fall under the category of switching power supplies. Isolated designs comply with UL and CE standards and use a well-insulated transformer, ensuring safety but at increased costs and decreased efficiency. Non-isolated innovations are usually adopted for low-power inbuilt systems.

LEDs typically require a constant current source. But sometimes, a continuous voltage driver paired with a regulator or resistor can be used. Signs and strip lighting use constant voltage drivers, providing greater flexibility in light adjustment, while most general lighting prefers stable current drivers.

These categories are based on the IEC standards for power supply construction and electrical insulation. Class I drivers need earth connections and primary insulation, whereas Class II drivers have higher insulation levels without an earth connection.

As per NEC guidelines, Class 1 and 2 differ based on output limitations and design requirements. Class 2 drivers, constrained by specific voltage, current, and power limits, offer cost savings on insulation and safety measures. UL1310 and UL8750 define Class 2 LED driver standards.

Modern lighting often incorporates dimming capabilities. Some notable methods include:

0-10V/1-10V dimming LED Driver

Triac dimming LED Driver

DMX dimming LED Driver

Other LED Driver Protocols

The IP (ingress protection) rating in IEC 60529 denotes an LED driver’s waterproofing level. This rating consists of two numbers: the first indicates solid object protection (0 being no protection, 6 being dustproof), and the second indicates liquid protection (0 being no protection, with higher numbers indicating increased waterproofing). While taller IP-rated drivers are commonly used outdoors, some indoor applications also use them for enhanced power and longevity.

In the early days of light bulb development, a component was integrated into bulbs to regulate the flow of electricity. This component, known as ballast, ensured the electrical current didn’t surge too high. Traditionally, ballasts have been essential for bulbs such as T8s and tube lights. They are still found in bulbs and lamps, especially with HID, metal halide, and mercury vapor lights.

Also referred to as inductors, magnetic ballasts create the optimal electrical conditions for specific lamps to function. They operate similarly to transformers, producing consistent electricity.

Introduced in the 1960s, they gained popularity between the 1970s and 1990s. They were commonly found in HID lamps, Metal Halide lamps, mercury vapour lamps, and more.

Before the rise of LEDs around 2010, these ballasts were a standard in significant parking lots and street lights for approximately three decades.

This ballast utilizes a circuit to regulate the current load. Electronic ballasts became prevalent in the 1990s and are used today, offering a more consistent and precise electrical flow than their magnetic counterparts.

The primary role of a ballast is to control the electricity supplied to a bulb, ensuring the bulb receives sufficient power without overloading. Lamps lack inherent regulation, making them susceptible to drawing erratic electricity levels. A ballast stabilizes this input, ensuring the light gets the right amount of electricity, even from high-power sources.

LEDs are distinct from traditional bulbs in several ways:

Fluorescent lights and LEDs require an intermediary between the bulb and the power source. Whereas traditional incandescent lamps rely on heating a filament to produce light, LEDs use LED drivers instead of ballasts.

Fluorescent ballasts initiate a high-voltage spike at the start, regulating the current afterwards. Conversely, an LED driver adjusts the power source to the precise voltage and current, illuminating the LED.

To function, LEDs need their alternating current converted to direct current, which the LED driver achieves. While ballasts have evolved over the years, they aren’t compatible with LEDs or other low-energy lights. The introduction and optimization of LED drivers have gradually replaced the need for ballasts, given their enhanced efficiency and adaptability.

Steps to Successfully Install an LED Driver:

Are you interested in adjusting the brightness of your LEDs? Opt for a driver with dimming capabilities. The operational mechanism of these power supplies is straightforward to understand. The product specifications often detail the types of dimmers compatible with these drivers.

Prioritize understanding the voltage needs of your lamp. For instance, if your LED functions at 20 volts, ensure you get a 20-volt driver.

Essentially, it’s vital to match the power needs of your LED with the Driver’s output. For constant-voltage drivers, you’ll focus mainly on the voltage range. However, with a constant-current driver, you’ll need to look at both voltage and current ranges. Always ensure the Driver can accommodate the LED’s power requirements, including stepping down to the necessary output voltage.

Also, remember to check the wattage. Always opt for a driver with a maximum wattage higher than your LED’s consumption.

The power factor indicates the efficiency with which the Driver utilizes electricity from the grid. Typically, the range lies between -1 and 1, with a power factor of 0.9 or higher being ideal. The closer this value is to one, the more efficient the Driver.

Ensure your LED drivers are compliant with recognized safety standards. For instance, UL Class 1 drivers are suitable for higher voltage applications and can accommodate more LEDs, enhancing efficiency. These drivers need a secure setup due to the high voltage output.

On the other hand, UL Class 2 drivers, which adhere to UL1310 standards, offer a safer operation but have a limitation on the number of LEDs they can power.

Another safety indicator is the IP rating. A rating like IP67 suggests that the Driver is protected against dust and can handle short-term immersion in water.

Efficiency is a pivotal factor, as it denotes the power consumption efficacy of the LED driver. This metric is usually presented in percentages, indicating that, for example, an 80% efficiency means the Driver operates effectively 80% of the time.

LEDs function best with low voltages, typically between 12 and 24 volts of direct current (DC). Thus, if you’re dealing with an alternating current (AC) voltage ranging from 120 to 277 volts, an LED driver effectively converts this AC voltage to DC. Essentially, this transition from AC to DC is crucial. Moreover, the Driver ensures that the optimal range of high and low voltage is achieved.

LED drivers are vital in shielding LEDs from voltage or current fluctuations. When an LED’s voltage varies, its current supply might also shift. This means the light intensity emitted by an LED is inversely proportional to its number. LEDs are designed to operate within a specific threshold. Therefore, too little or excessive current can either reduce the brightness or expedite the degradation of the LED, primarily due to overheating.

In summary, the primary advantages of LED drivers are:

While most light sources can be quickly switched off by adjusting the voltage, LEDs are unique. They are only turned off by modifying the ratio of voltage to current. As a result, LED dimming techniques differ:

Almost every LED light source requires a driver. However, the real question is, “Do I need to purchase one separately?” Some LED bulbs already have an integrated driver. For instance, LEDs designed for residential use, like those 120-volt bulbs with GU24/GU10 or E26/E27 bases, typically come with drivers.

Low-voltage LED varieties such as tape lights, MR bulbs, outdoor lights, panels, and other fixtures necessitate an LED driver for proper operation. While you need LED drivers for low-voltage LEDs, the same isn’t true for 120-volt LED bulbs commonly used in homes.

LEDs can be integrated into both HighBay and print mounting setups, contingent on the requirements of a project. For tighter spaces, SMD (surface-mounted device) LEDs are suitable. These LEDs can be soldered directly onto printed circuit boards, eliminating the need for wires. However, always ensure that all components are compatible.

In larger spaces where more illumination is essential, like factory halls or department stores, powerful HighBay spotlights are employed. These potent ceiling lights must be individually wired, often to a standard mains voltage of 230V AC. They’re paired with drivers such as the XBG-160-A to prevent the LEDs from overheating. These drivers include overload protection, effectively regulating the current supplied.

Determining the appropriate LED driver for your project requires the following information:

Additionally, other technical considerations may come into play. For instance, if you require meticulous colour control or the environment poses a risk of water contact, it can influence your choice of LED drivers. The water resistance of an LED is indicated by its IP rating. A higher IP rating denotes better water resistance. For example:

LED drivers play a pivotal role across various sectors, mirroring the versatility of LEDs themselves. With the array of transformers, power supplies, and drivers, illuminating your space becomes a breeze. The inherent adaptability of LEDs makes it simple to integrate intelligent functionalities and adjust luminosity. Thus, LED drivers are crucial for achieving contemporary, functional, and cost-efficient lighting solutions.

MyLikeLed produces top-tier LED strips and neon flex. Our offerings undergo rigorous testing in advanced labs to guarantee unparalleled quality. Moreover, we provide tailored solutions for our LED strips and neon flex. For superior LED lighting products, reach out to MyLikeLed today!

LEDs require constant current or voltage, which typical power sources don’t provide directly. An LED driver helps regulate power, preventing flickering or early failure.

Choose a driver based on the type of LED, its voltage/current requirements, total wattage, and dimming options if needed. Always match the driver to your LED’s specs.

No. Using the wrong driver can damage the LED or cause it to not work properly. Always ensure the driver’s output matches your LED’s input needs.

A dimmable LED driver allows you to adjust the brightness of your LED lights using a dimmer switch, remote, or smart control system.

LED drivers typically last 30,000 to 50,000 hours, depending on the quality, usage, and operating conditions. High temperatures or overloading can shorten their lifespan.

Hi, I’m Xylia Xiong, a sales professional with 14 years of experience in the LED strip light industry. I specialize in providing tailored solutions, leveraging my expertise in LED products and the latest industry trends. Known for effective communication and problem-solving, I’m dedicated to helping lighting manufacturers, importers, and distributors achieve their goals.

Let’s work together to create customized solutions that exceed expectations.