LED Aluminum Profile

- 500+ Models

- 6063-T5 Aluminum, White, Black, Silver Available

- PC / PMMA Cover, Clear / Diffuser / Opal Available

- OEM, ODM, and Mold Customization Available

What Is an Aluminum Profile for LED Strip Lights?

An aluminum profile for LED strip lights is a specially designed housing that enhances the performance, durability, and aesthetics of LED strip lighting. Also known as LED aluminum channels or aluminum extrusions, these profiles serve two main purposes: they act as diffusers to create smooth, uniform lighting effects and as installation channels for secure and professional LED strip mounting. Common types include surface-mounted, recessed, ceiling, and corner LED profiles, each catering to different lighting applications. Additionally, aluminum profiles function as heat sinks, improving thermal management and extending the lifespan of LED strips.

These versatile LED profiles can be seamlessly installed in cabinets, ceilings, stairs, walls, and floors, providing a sleek, modern look while concealing LED strips for a clean, professional finish. Their linear design, uniform light diffusion, and hidden silhouette make them a preferred choice for achieving high-quality lighting effects in both residential and commercial spaces.

Aluminum Profile Manufacturer & Supplier

My Like LED is a professional LED lighting manufacturer that supplies a wide range of LED Aluminum profiles, PC/PMMA covers, End Caps, Fasteners, and other accessories for high-end markets in more than 66 countries worldwide. We offer various full ranges from small LED profiles in 5mm width to lighting luminaries in 450mm width. The LED aluminum profiles cover all installations such as Sus-Pendant, Recessed, Surface mounted, In-ground, etc. Our products can meet the needs of the furniture industry, exhibitions, stage design, interior design, and many other fields. The LED aluminum profiles are qualified in CE and RoHs standards.

Different Types of LED Aluminum Profiles

Installation-Based LED Aluminum Profile:

- Surface Mounted LED Aluminum Profiles

- Recessed LED Aluminum Profiles

- Pendant LED Aluminum Profiles

- Corner LED Aluminum Profiles

- Wall LED Aluminum Profiles

- Floor LED Aluminum Profiles

Specialized LED Aluminum Profiles:

- Mini LED Aluminum Profiles

- Lens LED Aluminum Profiles

- Bendable LED Aluminum Profiles

- Waterproof LED Aluminum Profiles

Functional LED Aluminum Profiles:

- Wardrobe Closet Hanging LED Aluminum Profiles

- Shelf Magnetic LED Aluminum Profiles

- Glass Shelf LED Aluminum Profiles

- Snake Bending LED Aluminum Profiles

- Ring Circular LED Aluminum Profiles

Surface Mounted LED Aluminum Profile

LED strip profiles mounted to any surface easily, a great choice of adding light to existing structures.

Recessed LED Aluminum Profiles

LED strip profiles recessed into mounting surfaces to achieve a flush look, integrated into surroundings.

Pendant LED Aluminum Profiles

Our pendant LED aluminum profiles range offers versatile, modern, and practical lighting solutions for many different applications. The linear LED lighting effect is perfect for above your desk, reception areas, meeting room tables, and more.

Corner LED Aluminum Profiles

Aluminum profiles mounted in corners, setting angled light beam to illuminate desired areas.

Wall LED Aluminum Profiles

The wall LED aluminum profiles for drywall/plasterboard/marble/tile structure, which can be mounted on the surface of the dry wall and used for the linear lighting system for the architectural designs.

Floor LED Aluminum Profiles

These specially designed aluminum profiles are made to illuminate steps and staircases using low voltage LED strip lights. Not only do these aluminum profiles provide safety while lighting steps and stairs but they also have ribbed tops for gripping and traction. With proper sealing techniques these channels can be used in outdoor architectural applications. Stop tripping over dark stairs and provide safety for your home and business guests with these specially designed aluminum profiles and LEDYi LED strips lights.

Mini LED Aluminum Profiles

Mini LED aluminum profiles are a collection of small-size aluminum channels. They can be installed in some narrow places.

Lens LED Aluminum Profiles

Lens LED aluminum profiles have diffuser cover lens, can achieve a small beam angle.

Bendable LED Aluminum Profiles

The bendable LED Aluminium profiles are flexible and can fit into any desired shape. These LED profiles come in various wattage & ingress protection of IP20 available in lengths of 0.5-3M. Transparent and Opal PC covers/ diffusers with surface mounting accessories help to form uniform lighting. They are made available with high-grade aluminum AL6063-T5 and powder coated in silver/black/white finishes. Different profiles can be combined with LED strip lights to create infinite architectural and interior lighting solutions.

Waterproof LED Aluminum Profiles

The Waterproof Aluminium profiles come in various wattage & ingress protection of IP65 available in lengths of 0.5-3M and can be used outdoor.

Wardrobe Closet Hanging LED Aluminum Profiles

The wardrobe closet hanging led aluminum profile is a wardrobe rail extrusion that you can hang your clothing from as a traditional garment rack would, but it doubles as a light fixture. The fixture can house led strip light which directs light onto all articles of clothing hung from it. Constructed from high quality 6063-T5 aluminum alloy, this heavy-duty extrusion rail is robust and adds an additional layer of light to any wardrobe.

Shelf Magnetic LED Aluminum Profiles

A unique magnetic lighting system can create a lighting relationship between architecture and space. This offers new creative opportunities for integrating light into a space. It also has an incredible impact on the ambiance of the interior. These profiles are small, lightweight, and easy to move, which helps the user adjust the direction easily.

Glass Shelf LED Aluminum Profiles

The glass shelf LED aluminum profile illuminates the glass shelf mounted within its brackets. You can install it on walls or inside cabinets, improving visibility.

Snake Bending LED Aluminum Profiles

Snake Bending LED Aluminium Profiles can be bent horizontally with a flexible silicone cover. It can be used for advertising, signage lighting, etc.

Ring Circular LED Aluminum Profiles

Ring Circular LED profiles are designed in a round shape. Commonly, these are suspended LED channels that hang from the ceiling.

Why Choose LED Aluminum Profiles?

The LED strips in the aluminum profiles with diffusers emit a softer and more comfortable light than the lights without diffusers, as shown in the picture below. The diffuser eliminates the glare of the lighting. The light is kinder to the eyes and helps to protect your eyesight. In addition, aluminum profile lights look better. When installed in a proper aluminum profile with diffuser, it provides spotless illumination.

As well as being used as heat sinks to enhance heat dissipation, LED aluminum profiles, together with LED strips, are an essential element in the individual lighting favored by many lighting designers. They have countless advantages.

Enhances the aesthetics of the lighting

The aesthetic appearance of improved linear lighting with aluminum profiles creates fantastic illuminated shapes for spaces. Its contours can add layers to the interior environment when the led strip is installed.

If the shape of linear lighting is used correctly, a house with a simple structure can produce stunning results. You could say that light strips are the home’s little make-up! Use for commercial purposes to display more attractive merchandise. They are exquisite and very eye-catching.

Enhanced heat dissipation

As a heat sink, the LED aluminum profile absorbs the heat generated by the LED strip during operation and distributes it into the air through the channel surface. The improved thermal management system extends the life of the LED strip.

Protection for LED strips

The anodized aluminum profile provides a robust housing for LED strips that protects them from water, dust, UV radiation, weather conditions, and unwanted effects. It can be used, for example, for strip lighting in splash areas.

Easy fit

Aluminum profiles can be seamlessly recessed into recesses in cabinets, staircases, walls, and floors. They take up very little space but provide light exactly where you want it without the sight of bulky luminaires.

Work as led strip diffusers

The aluminum profile cover is often called an LED strip diffuser. It can be frosted or opal to provide optimum light diffusion for a perfectly spotless and more even illumination and avoid glare.

Helps with the installation of LED strips

Aluminum profiles can help to mount LED strips in different ways. For example, some surfaces are uneven, rough, or greasy and are unsuitable for attaching LED strips. Aluminum profiles allow mounting LED strips to these surfaces. Aluminum profiles can also be used as a bridge to fill the gap between two different mounting characters.

Easy to form different shapes

DIY lighting shapes are easy. Aluminum profiles can easily be cut at the end for angular connections to form a square, triangular, L-shaped, or tree-shaped lighting designs. Easily create a more personalized light.

LED strips can be easily replaced. The internal light strip can be easily removed and replaced if the user wants a different color strip.

Safety

The LED strip profile is designed for low voltage strips. Very safe to install and use.

Considerations Before Buying LED Aluminum Profiles

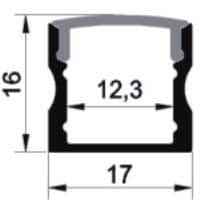

The inner width of led aluminum profiles

There are typical lengths such as 1meter, 2meter, 2.5meter, and 3 meters in the market. Before choosing your profile length, you should clarify which shipping way you like to ship your led aluminum profile: air shipment or sea transportation. If you choose air shipment, you will better select the length within 3meter in case of extra shipping cost. But if you choose economical sea transportation, the length will be a free choice. You can ask your supplier to make any customized length available for container loading.

The depth of the led aluminum profiles

The depth of the LED aluminum profile has two effects on the installation and use of the led strip lighting.

1. The depth of the LED strip profile needs to match the depth of the mounting groove. Remember, the thickness of the mounting surface will limit the depth of the groove.

2. The depth of the aluminum profile determines the led strip pitch and the diffuser. This distance affects the uniform distribution of light. For the same LED strip, the deeper the profile, the more evenly the light will be distributed. The higher the LED density, the better the light distribution of the LED strip if the depth of the profile is constant.

The length of led aluminum profiles

There are typical lengths such as 1meter, 2meter, 2.5meter, and 3 meters in the market. Before choosing your profile length, you should clarify which shipping way you like to ship your led aluminum profile: air shipment or sea transportation. If you choose air shipment, you will better select the length within 3meter in case of extra shipping cost. But if you choose economical sea transportation, the length will be a free choice. You can ask your supplier to make any customized length available for container loading.

Shapes of led aluminum profile.

Most led aluminum profiles are U shape channels. U shape led aluminum profiles are used widely. Of course, there are other different shapes, such as angle or round aluminum profiles, to match different needs of installation. For example, the corner aluminum profile is suitable for corner installation. Aluminum u channel can have wings or no wing, also called flange. LED profiles with flange can help cover uneven grooves. Different shape led aluminum profiles are available for different installations. Which shapes of the led profile are the best choice? Ask yourself where you want to install the led profile and what lighting effect you want to achieve. The more precise you know about the lighting project, the better you will make a choice.

Covers of led aluminum profile

The cover of the LED aluminum profile provides dust, moisture, and UV radiation protection for the LED strips inside the aluminum profile. The cover can also be used as a diffuser or lens for the LED strip. Covers can be transparent, frosted, or opal. Each type of cover produces a different illumination. Clear covers are transparent and allow light to pass through without less reducing brightness. A frosted cover is translucent and reduces the brightness slightly. However, its primary function is to achieve even light and avoid glare. A spotless illumination is achieved with the opal cover, and the LEDs are not visible. We have the above three colors of plastic cover available for customers to choose from.

The quality of the led aluminum profiles

The best aluminum alloy for making led aluminum profiles is 6063 T5. Besides this, the anodized layer of an aluminum profile should reach 8-13 micrometers, and the painted layer should reach 60-80 micrometers. The thicker layer, the better the corrosion resistance.

For the cover part, the thickness of covers we often make is 1.2mm for slim ones and 1.4mm for big size ones.

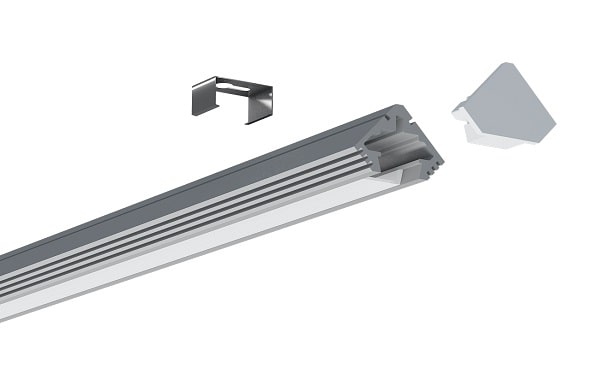

Accessories of led aluminum profiles

End caps and brackets are small accessories of led aluminum profiles. The material of small end caps is ABS or PC, the surface of its often processed with wet oil painting to match the color of the led aluminum profile. For bigger size end caps, it’s usually made of metal, like aluminum alloy or other metals. These bigger size end caps are designed without holes on the surface, but only one hole on top of it to be fixed with led aluminum profiles by machine-processed rice screws. For metal end caps, always be textured. It’s fire-resistant and safe than that plastic end caps. The most crucial point is that there is no light leakage from this metal end cap.

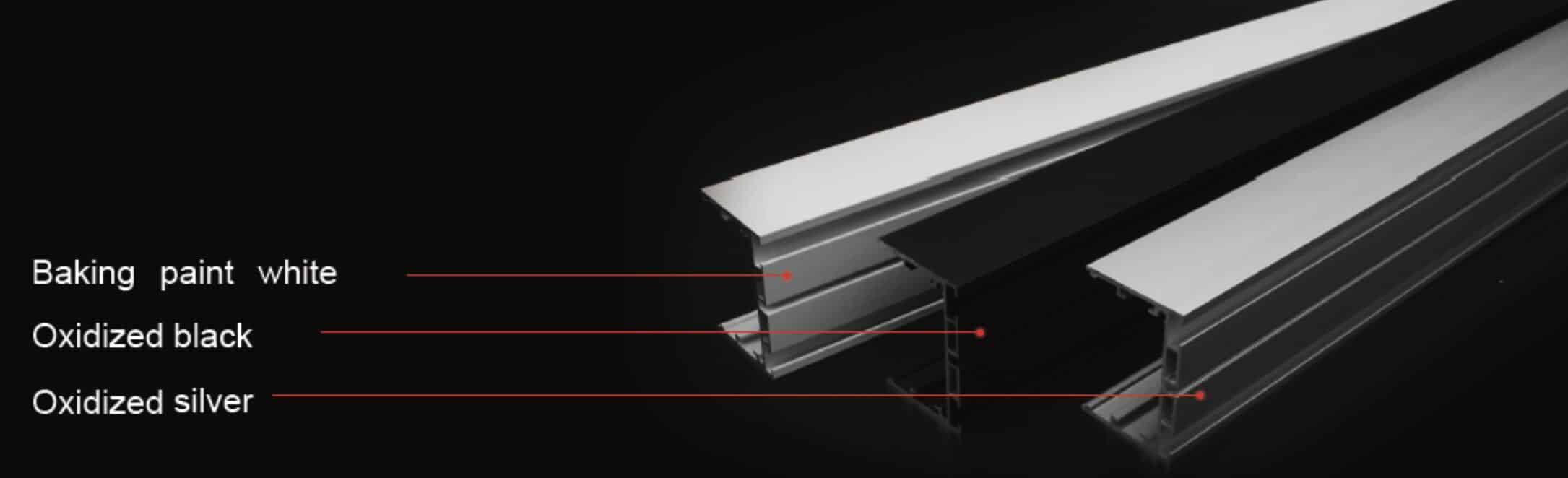

Colors of led aluminum profile

Anodized silvery, painted white, and black is three primary colors for the led aluminum profile. The black color can also be achieved by anodizing, but the cost of anodized black is a little more expensive than painted black. Three colors seem too minor for the actual operating condition. There is always a project that requires unique colors. Such as dark brown, golden, blue, etc. Remember that color is not difficult to achieve, but the quantity and cost will be the first thing to consider.

Design

Do you have any ideas about the led profile design? If you have some knowledge about led profile structural design, you will choose the simple structure design but with good quality led profile from the market. For example, led aluminum profiles with a movable middle plate are better designed than that unmovable ones. We can quickly put the led driver into the led profile with a movable central part.

How To Install LED Aluminum Profile?

The installation of the LED aluminum profile includes three steps. Install the aluminum profile, install the LED strip into the aluminum profile, and install the aluminum profile cover. The order of these three steps varies depending on the type of installation. I will explain the detailed installation steps step by step below.

Step 1: Mount the LED aluminum profile

LED aluminum profiles are easy to install due to their lightweight. Depending on the shape and function of the LED aluminum profiles, they can be surface mounted, recessed or flush-mounted, corner mounted, or suspended. LED profiles are usually mounted using mounting brackets, screws, 3M double-sided tape or mounting adhesive, suspension cables, and fasteners.

You can mount the LED strip light channel directly on a wall, ceiling, or other surface using mounting brackets, 3M double-sided tape, or screws. Mounting brackets usually have pre-drilled holes. You can quickly fix them on the wall with screws. Then, the aluminum profile snaps into the mounting brackets.

Installing an LED strip light channel with 3M double-sided tape is as easy as peeling and sticking. This installation requires the preparation of the mounting surface and ensuring it is clean and dry. Use isopropyl alcohol as a cleaning solvent and use acetone instead for the oily substrate.

Since the LED profile is made of aluminum, it is also easy to penetrate with a screw so that the aluminum profile can be easily fixed to the mounting surface.

The aluminum profile is mounted behind a wall or other surface with the contoured opening flush with the surface. It would be best if you dug a recess in the mounting area to match the width and depth of the LED strip channel.

Are you worried about the recess opening being uneven or too wide? Don’t worry. LED aluminum channel tracks with lips (also known as wings or flanges) on both sides. When flush-mounted, they can overlap unpleasant recess edges or gaps.

Some LED aluminum profiles have two recesses in the side walls. Use the mounting clips to clamp onto the first or second recess to adjust the mounting height and the cooling distance between the LED profile and the recess base on the mounting surface.

The angle LED aluminum channel is used as an angle mounting substrate for LED strips, providing beam angles of 30°, 45°, and 60° concerning the mounting surface and creating ambiance in the corner areas of the room. Corner mounting is made easy by using mounting brackets, double-sided adhesive tape, etc.

For corner mounting, the LED aluminum channel makes good use of space unavailable to other luminaires. In addition, special attention needs to be paid to dark corners when designing lighting schemes. Corner-mounted LED profiles easily brighten up corners stylishly and elegantly. Where does the high thermal performance of corner-mounted LED profiles come from? Let’s take the example of the 45° beam angle LED profile. The corner-mounted profile has an internal base at a 45° angle to the two walls of the profile. The inner base and the two walls of the LED channel form a cavity which enhances the cooling of the LED strip and the cooling of the channel.

LED extrusion profiles have been more and more used in elegant strip lighting for modern spaces. Hanging the LED extrusion profile from the ceiling is a new way to create contemporary lighting in the air. Pendant cables, buckles, and fasteners are usually used to hang the LED profiles.

Step 2: Install LED strip lights into the LED extrusion profile

This is the typical peel-and-stick installation. Peel off the protection liner of the 3M double-sided tape and stick the LED strip to the inner base of the aluminum channel.

Step 3: Pair the LED aluminum channel with cover

Line the cover with the LED aluminum channel at one end, and squeeze the cover into the holding grooves on the inner walls of the channel. Then press to the other end. You can tell by the click sound if the cover sits in the position.

What is Aluminum Extrusion?

Aluminum extrusion is when aluminum alloy material is forced through a die with a specific cross-sectional profile.

A powerful ram pushes the aluminum through the die, and it emerges from the die opening. When it does, it comes out in the same shape as the die and is pulled out along a runout table. At a fundamental level, aluminum extrusion is relatively simple to understand. The force applied can be likened to the force you apply when squeezing a tube of toothpaste with your fingers.

As you squeeze, the toothpaste emerges in the shape of the tube’s opening. The opening of the toothpaste tube essentially serves the same function as an extrusion die. Since the opening is a solid circle, the toothpaste will come out as a long solid extrusion.

The Aluminum Extrusion Process in 10 Steps

The use of aluminum extrusion in product design and manufacturing has increased significantly in recent decades. Today we’ll discuss what aluminum extrusion is, the benefits it offers, and the steps involved in the extrusion process.

- A round-shaped die is machined from H13 steel or retrieved from storage.

- The die is preheated to 450-500°C for longevity and even metal flow.

- Once preheated, the die is loaded into the extrusion press.

- A cylindrical aluminum billet is cut from a longer log.

- It is preheated to 400-500°C, making it malleable but not molten.

- The billet is mechanically transferred to the extrusion press.

- A lubricant is applied to both the billet and the extrusion ram to prevent sticking.

- The billet is loaded into the extrusion press.

- A hydraulic ram applies up to 15,000 tons of pressure, pushing the billet into the container.

- The material expands to fill the container walls.

- The billet is pressed against the die, forcing the aluminum material through the die’s openings.

- The material emerges in the shape of a fully-formed profile.

- A puller grips the extrusion and guides it along the runout table at a synchronized speed.

- The extrusion is uniformly cooled by a water bath or fans.

- Once at full table length, the extrusion is sheared by a hot saw.

- Although quenched, the extrusion has not yet fully cooled.

- The extrusions are transferred to a cooling table.

- They remain there until they reach room temperature before stretching.

- The extrusions undergo natural twisting and require straightening.

- They are mechanically gripped on both ends and pulled into proper alignment.

- Straightened extrusions are transferred to the saw table.

- They are cut to pre-specified lengths (8 to 21 feet).

- At this stage, they match the T4 temper and can be aged further to T5 or T6 temper.

What Happens Next? Heat Treatment, Finishing, and Fabrication

Once extrusion is completed, profiles can be heat treated to enhance their properties. Then, after heat treatment, they can receive various surface finishes to enhance their appearance and corrosion protection. They can also undergo fabrication operations to bring them to their final dimensions

- Alloys in the 2000, 6000, and 7000 series can be heat treated to enhance their ultimate tensile strength and yield stress.

To achieve these enhancements, profiles are put into ovens where their aging process is accelerated and they are brought to the T5 or T6 tempers. How do their properties change? As an example, untreated 6061 aluminum (T4) has a tensile strength of 241 MPa (35000 psi). Heat-treated 6061 aluminum (T6) has a tensile strength of 310 MPa (45000 psi). It is important for the customer to understand the strength needs of their project to ensure the right choice of alloy and temper. After heat treating, profiles can also be finished.

Aluminum profiles can undergo a number of different finishing operations. The two main reasons to consider these is that they can enhance the appearance of the aluminum and can also enhance its corrosion properties. But there are other benefits as well.

For example, the process of anodization thickens the metal’s naturally-occurring oxide layer, improving its corrosion resistance and also making the metal more resistant to wear, improving surface emissivity, and providing a porous surface that can accept different colored dyes. Other finishing processes such as painting, powder coating, sandblasting, and sublimation (to create a wood look), can be undergone as well. In addition, there are many fabrication options for extrusions.

Fabrication options allow you to achieve the final dimensions that you are looking for in your extrusions. Profiles can be punched, drilled, machined, cut, etc. to match your specifications. For example, the fins on extruded aluminum heatsinks can be cross machined to create a pin design, or screw holes can be drilled into a structural piece. Regardless of your requirements, there is a wide range of operations that can be performed on aluminum profiles to create the perfect fit for your project.

Plastic Cover Extrusion Process

Plastics extrusion is a high-volume manufacturing process in which raw plastic is melted and formed into a continuous profile. Extrusion produces items such as pipe/tubing, weatherstripping, fencing, deck railings, window frames, plastic films and sheeting, thermoplastic coatings, and wire insulation. This process starts by feeding plastic material (pellets, granules, flakes or powders) from a hopper into the barrel of the extruder. The material is gradually melted by the mechanical energy generated by turning screws and by heaters arranged along the barrel. The molten polymer is then forced into a die, which shapes the polymer into a shape that hardens during cooling.

LED Aluminum Profile Applications

The LED aluminum channels are available in various shapes and functional designs, making them suitable for almost any space. The length is easily adjustable. If you need it to be long, you can join several sections together. If you need a short aluminum profile, it is easy to cut it short. Thanks to this flexibility, LED aluminum profiles can be used to design strips of lighting for any space successfully.

With LED strips, covered LED aluminum channels are already widely used for interior lighting, especially under-cabinet lighting, ceiling lighting, display cabinet lighting, staircase lighting, accent lighting, and decorative lighting for walls and floors.

When used with our outdoor waterproof LED strips, they are suitable for outdoor lighting in landscapes, gardens, courtyards, balconies, and walkways. Below are typical examples of LED aluminum profiles. But remember, your imagination knows no bounds for LED profile applications.

Why You Should Choose Us?

When you choose LED strips in bulk from us, you’re not just getting a product; you’re gaining a reliable partner dedicated to providing you with top-notch quality, competitive pricing, and unparalleled support.

My Like Led的产品经过各种质量测试,为用户提供高端产品。这里有几个原因,为什么你应该从我们这里得到单色led灯带。

Premium Quality Guaranteed

Our commitment to quality is unwavering. Every single color LED strip that leaves our production line undergoes stringent quality control measures.

Extensive Range of Options

We offer a comprehensive range of single color LED strips with various lengths, brightness levels, and color temperatures. You'll have the flexibility to select the perfect fit for each application.

Competitive Bulk Pricing

By partnering with us for wholesale purchases, you gain access to competitive bulk pricing. Our streamlined manufacturing processes and efficient supply chain management enable us to offer you cost-effective solutions without compromising on quality.

Expertise and Technical Support

Whether you need assistance in selecting the right product or guidance on installation, our technical support team is always ready to help.

Timely Delivery

We understand the importance of timely deliveries in your business operations. With our efficient logistics network, we ensure that your bulk orders are delivered promptly and reliably, keeping your projects on track.

Global Market

Products are exported to over 60 countries and regions worldwide. Dominates the European market and cooperates with many major well-known brands.

FAQs

Good-quality LED aluminum profiles are usually made from high-quality anodized aluminum. This provides excellent heat dissipation, durability, and corrosion resistance.

Yes, you can order LED aluminum profiles of your required length and size to meet specific applications. We offer extensive customization facilities.

Our LED aluminum profiles offer a variety of sizes and designs. You will easily find compatible profiles from these. Moreover, with our extensive customization facility, we ensure compatibility for varin g LED strip wide, size, and installation requirements.